Industrial revolution: meet the makers from Wellington’s design-led manufacturing sector

Businesses across the Wellington region, both old and new, are leading the movement to switch manufacturing from traditional resource-intensive methods to design-led, value-added, efficient processes.

The high-value manufacturing sector makes a significant contribution to the region’s economy (manufacturing had the fourth highest share of Wellington’s GDP earnings at 7.5 percent, or $2.25 billion in 2016). And the more Wellington continues to regenerate its manufacturing industry with innovative technology, the better it is for the community.

Economists agree that creating one job in a manufacturing business leads to the creation of two-to-three additional jobs in supporting industries.

Wellington manufacturers produce a diverse range of products, from beer and chocolate through to animal vaccines and scientific instruments, plastics, print and machinery.

So, what does the design-led manufacturing sector look like?

Making hay

A bunch of exciting new businesses have popped up like wildflowers in the shuttered factories of Wellington industries of old.

Take Wellington’s thriving craft beer market. Garage Project’s brewery is in an old petrol station in Aro Valley, while Panhead Custom Ales is based out of a converted Dunlop tyre factory in Upper Hutt.

In many cases, high-quality, design-led industries such as craft beer brewing have replaced traditional, and in some cases less sustainable, factories that shouldered Wellington in the past.

Award-winning craft beer brewery Panhead opened its plant in the old tyre factory in 2013. It is already part of the establishment after last year being bought out by Lion for an estimated $25 million.

For Panhead, self-described as “New Zealand’s beer bogans”, operating out of Wellington makes sense. It’s close to the biggest, thirstiest market for craft beer in the country, general manager Josh Drake says.

“A lot of New Zealand’s food trends attracted critical mass here and beer is a big one. We’ve got an educated, adventurous, well-paid population and a size and structure that allows ideas and experiences to socialise really quickly.”

The manufacturing of boutique beers is buoyed by other local design-led creative industries as Panhead takes inspiration from the film and software industries, tattoo artists, set-designers and hot-rodders, Drake says.

“The thing is, everyone in Wellington loves good beer. CEOs, creatives, government workers, students, builders, labourers, you name it. It’s not just a hipster thing.”

Painting the town red

Paint manufacturer Resene is an enduring success story for Wellington manufacturing.

Paint manufacturer Resene is an enduring success story for Wellington manufacturing.

Nestled in a two-storey building in Lower Hutt, Resene operates New Zealand’s largest privately-owned and operated paint manufacturing company.

It has more than 55 company-owned retailers and 40 re-sellers and stockists around New Zealand, and runs manufacturing operations in Australia, Fiji and Auckland, as well as the local production plants in Lower Hutt and Upper Hutt.

It has more than 55 company-owned retailers and 40 re-sellers and stockists around New Zealand, and runs manufacturing operations in Australia, Fiji and Auckland, as well as the local production plants in Lower Hutt and Upper Hutt.

Founded more than 70 years ago, the Resene team has seen industries in Wellington rise and fall, but has never considered going elsewhere, spokesperson Ashleigh Evans says.

“The infrastructure is here that supports the development and manufacturing of coatings. There are significant outside research institutions … distribution is straightforward from a central position and we are able to backhaul to bigger markets in the north.”

“The infrastructure is here that supports the development and manufacturing of coatings. There are significant outside research institutions … distribution is straightforward from a central position and we are able to backhaul to bigger markets in the north.”

Structural integrity

{% gallery ‘makers’ %}

Wellington’s robust architecture and design industries, supported by the internationally regarded Victoria University Architecture School, no doubt provides a healthy local network for Resene.

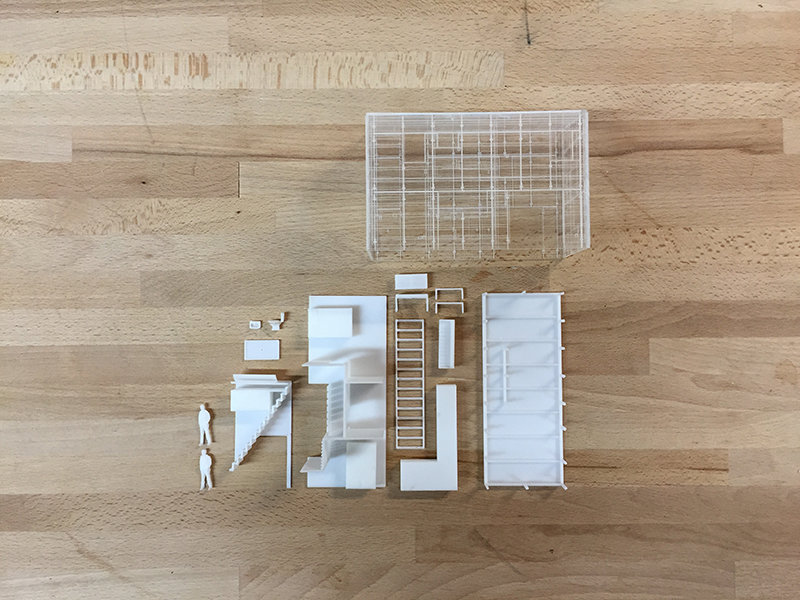

One firm within that local network is the award-winning Makers, which has two companies – Makers of Architecture and Makers of Fabrication.

In 2015, Makers, consisting of four Victoria University graduates, won the Small Project category for an innovative two-storey studio that took three days to erect. Judges said it was a first of its kind in New Zealand and lauded its precision and efficiency.

Using building information modelling and computer numerical control technologies the team handles all aspects of creating projects of varying scale for different locations.

By conducting full-scale prototypes, and digital and physical modelling, the team’s projects are erected much like a jigsaw puzzle, which reduces time and waste.

Makers’ Beth Cameron says working out of central Wellington has allowed for a number of collaborative projects and linked them with the city’s large architectural community, including other young startup companies doing innovative, unconstrained work.

“Wellington tends to be a well-supported incubator. There is a good energy around the development and support for industries, both developing technologies and manufacturing processes, while also providing new approaches to creative problem solving.”

Lighting the way

Manufacturing is experiencing a definite shift from traditional engineering-led design to a more customer-centric design approach, Vega’s Nina Ive says.

Manufacturing is experiencing a definite shift from traditional engineering-led design to a more customer-centric design approach, Vega’s Nina Ive says.

“Over the coming years you will see a lot more focus on the needs of the customer and the little design features that can make the use of the product much better.”

Vega started in Wellington in 1972 when a young Norman Rumsey – head of optics at the Department of Scientific and Industrial Research – was asked to design a light for Porirua’s Paremata Harbour.

Vega started in Wellington in 1972 when a young Norman Rumsey – head of optics at the Department of Scientific and Industrial Research – was asked to design a light for Porirua’s Paremata Harbour.

The company went on to design and manufacture specialised navigation lights for maritime authorities – ports and harbours – around the world. But the manufacturer has stayed loyally based in Porirua.

Like many of its Wellington peers, Vega’s focus on quality has minimised the challenges caused by globalisation.

“Because of our niche sector we were able to focus on the design and build of our products and our location didn’t matter so much,” Ive says. “We also had a strong ‘make-to-order’ philosophy so customers would come to us for the lights that they couldn’t get anywhere else.”

Growth in competition led Vega to work on a more standardised product range that meant shorter lead times. Determined to stay based in the region, Vega employed business development managers in four continents to ensure it remained top-of-mind for tenders.

Ive says Porirua remains the perfect location for Vega.

“Over the years we have built good supply partners who are often small local manufacturers like ourselves who have built specialist knowledge and innovative solutions.”

Dig this

Local and national exporting businesses are aware of the need to be design-led and continually strive for the next product innovation, Wedgelock CEO Matthew Culver says.

Local and national exporting businesses are aware of the need to be design-led and continually strive for the next product innovation, Wedgelock CEO Matthew Culver says.

“This is driven by a need to innovate or die which often involves patenting a new innovation. That requires a lot of resource and a good understanding of competitors’ current and emerging products.”

Wedgelock has designed and manufactured excavator coupling systems – accessories for diggers – since 1994. The company manufactures its products for local and export markets from a purpose-built facility in Upper Hutt where design and R&D teams are also based.

Wedgelock has designed and manufactured excavator coupling systems – accessories for diggers – since 1994. The company manufactures its products for local and export markets from a purpose-built facility in Upper Hutt where design and R&D teams are also based.

Wedgelock’s Upper Hutt home means it’s ideally located to attract staff from across the Wellington region with employees living not just in Porirua but the Kapiti Coast, Wairarapa, Hutt Valley and Wellington. It’s also well-suited for business logistics, Culver says.

“Our products are exported and Wellington’s port [CentrePort] provides an economic and active port for transportation from our factory to overseas markets.”

Culver says there’s no shortage of quality innovators in the region and Wellington businesses are attracting offshore talent.

“This will only enhance the Wellington region as a centre renowned for creativity and design.”

- Want to win a trip to Wellington? Mash your pointing device here, complete our quiz and you could win flights, accommodation and tickets to Beervana.