Potatoes and precious metals star in MOTAT’s sustainability showcase

A packaging manufacturer repurposing waste from potato chips and a business recovering valuable metals from e-waste are just two of the companies showcasing their innovative sustainability solutions at MOTAT’s Switch Up exhibit.

The immersive exhibition experience, created by the team at the Museum of Transport and Technology in Auckland (MOTAT), features 15 innovative companies from across Aotearoa, and is designed to educate and inspire tamariki to ‘switch up’ their actions to live sustainably.

Following my visit to the exhibition last month, and wanting to learn more about what inspired the innovation and smart designs on display at the exhibition, I sat down with two of the businesses making impressive impacts in the sustainability space in their own rights.

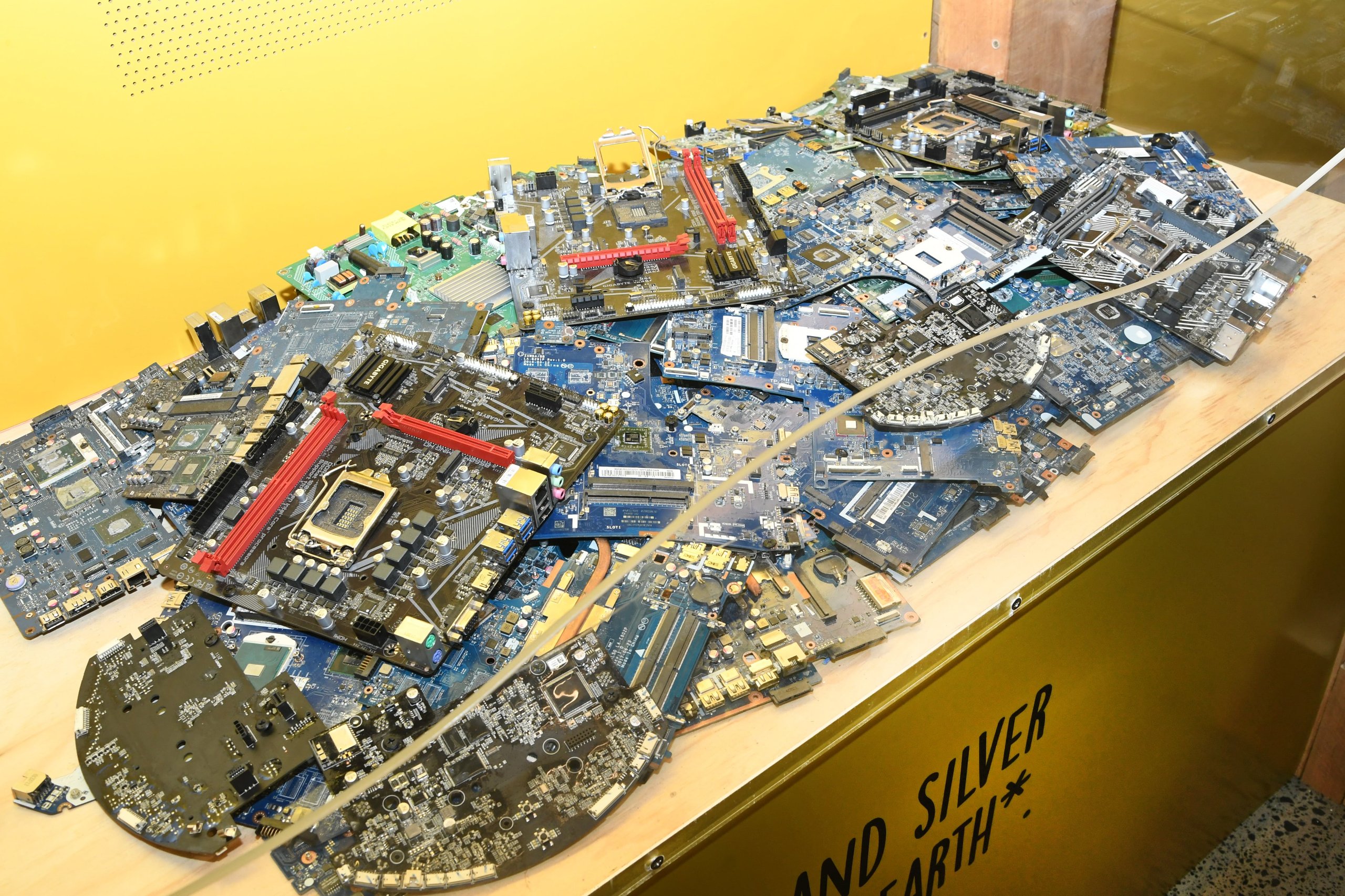

Founded just over six years ago, Mint Innovation is doing its bit for the environment by recovering valuable metals like gold, palladium and copper from e-waste such as old phones and laptops.

“We focus on end-of-life materials or end-of-life devices that are otherwise thrown away and typically concentrated,” says Dr Will Barker, Founder of Mint Innovation.

A typical iPhone contains anywhere from 50 to a few hundred milligrams of precious metal. The gold extracted from one tonne of circuit boards can be valued at $US12,000. By comparison, it takes around a tonne of rock to mine a gram of gold.

“We’ve got a sustainable solution that means less gold needs to be dug out of the ground,” says Barker.

“You can imagine that the carbon footprint of crushing all that rock, all that blasting, transferring it, transporting it to the surface is huge, and the concentrations of gold that are being found are going down,” he says.

“The waste associated with mining that and the environmental impact of mining, that’s just going up.”

Read more: Sustainable solutions for everyday life with MOTAT

Barker adds that miners also use chemicals such as cyanide to recover gold from virgin ores. Meanwhile, many of the valuable metals found in e-waste can end up in landfill and are harder to break down than other waste products.

The process to extract metals from e-waste begins with collecting waste from urban environments and sees Mint Innovation work with recyclers who break down the e-waste into different value fractions.

Recyclers will break down the e-waste, giving the circuit boards to Mint Innovation who recover the valuable metals using a patented process that has taken years to develop.

The metal recovered from the e-waste is then brought back to the industry to be reused and recycled, saving tonnes of metal going into landfill whilst also addressing how limited the metals are becoming.

The Auckland-based company is now looking for international opportunities, with the first international plant opening in Australia and the next planned for the UK.

“What we’ve developed is local capability to be able to recover the value where that waste stream is created, where those old obsolete cell phones and laptops are thrown away, and recover the metals in a very low carbon way, which if you think from a climate solution perspective is particularly attractive,” Barker says.

“If you are building something that is designed to be going into a city, it needs to address city scale waste streams.”

Being featured in MOTAT’s Switch Up: Sustainable Solutions exhibit has allowed Mint Innovation to share their story and promote the future of urban solutions for e-waste, while getting tamariki and families to think about what they could do with their technology at the end of its life-cycle.

Karla Bo Johnson, Lead Curator of the exhibit says she approached Mint Innovation due to the operations uniqueness and innovation when it came to looking at sustainable solutions.

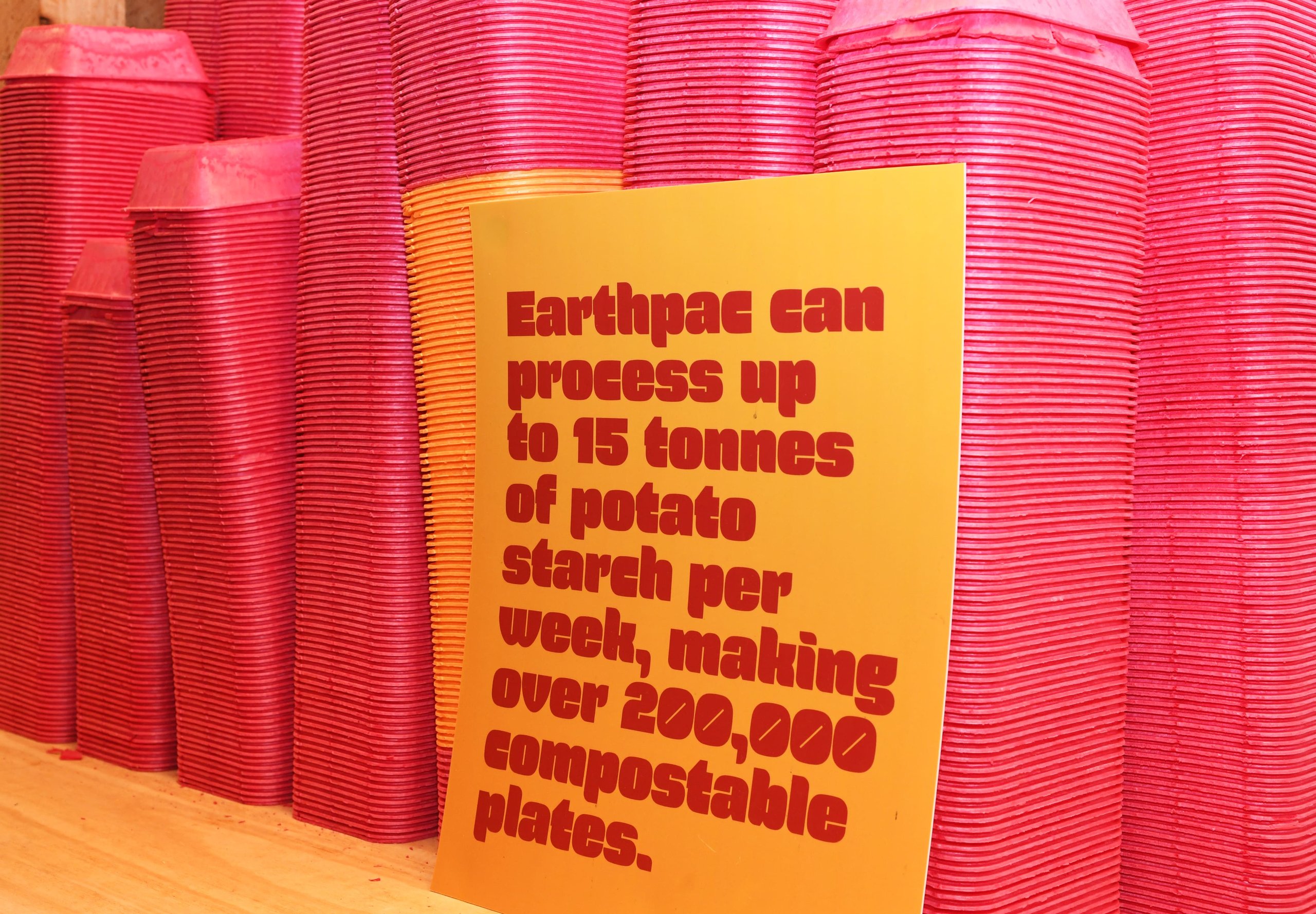

Another business featured in the exhibition is Earthpac which creates compostable packaging from potato starch found in the wastewater from the potato chip making process.

Founder Richard Williams says the business was developed to create a circular economy through upcycling and home composting to make “the perfect closed loop” a reality.

“We are using the starch from water that is left from cutting the potatoes at chip plants like Bluebird and Griffin’s. Instead of them having to throw the starchy water down the drain, they can recycle that water,” he says.

Williams says Earthpac goes through a process to remove the starch from the water, making the water clean and recyclable.

Starch in its raw form is an expensive product but biodegradable. Through the Earthpac process the starch is dried and sterilised, and then used to create biodegradable packaging.

“It’s the perfect closed loop because you’re not actually growing a product to create a product. You’re using a co-product and you’re up-cycling that product to turn it into something else,” he says.

Williams says many other companies that produce packaging use materials such as polystyrene, which are typically full of carcinogens, or plastic, a material that is not good for the environment.

Other packaging materials include bamboo fibre, which is carcinogenic and not good for composting.

“We are unique in the fact that we have no toxins in our products. It’s all food grade and you can easily home compost it, commercially compost it, put it in a landfill or feed it to a worm bin, and it’s not going to have an ill-effect on the environment,” says Williams.

During its years in operation, Earthpac has worked alongside Auckland Hospital, helping to save 11 tonnes of plastic trays from going to the landfill each year.

Williams says the business would like to get into more hospitals and hopefully save hundreds of tonnes of plastic trays a week.

It was a “no brainer” when MOTAT asked him about featuring in the Switch Up exhibit, he says. “Circular economy, sustainability, the environment, up-cycling and home composting are all priorities close to the heart of Earthpac, and everything the exhibit promotes.”

It’s inspiring to get an understanding of the breadth of innovative businesses in Aotearoa who are switching things up for sustainability and making earth a better place.