We all know the score: our trees are being chopped down at a record pace, meaning wood is disappearing even as we’re using more of it than ever before to build things. Something, somehow, needs to be done.

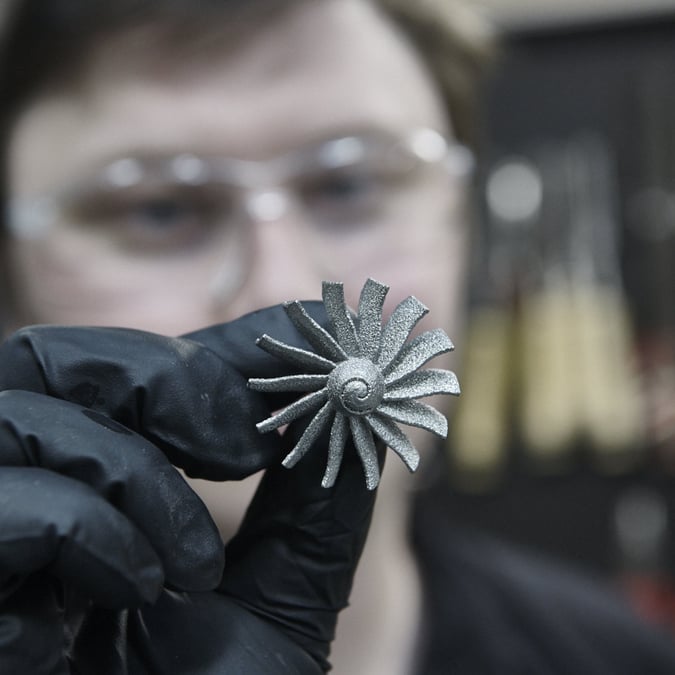

And something is. A University of Canterbury researcher has won Government funding to explore the potential for 3D printing live plant cells (a process known as bio-printing) to create synthetic wood. Associate Professor David Leung is working on creating a new, sustainable industry for synthetic wood manufacturing through the 3D bio-printing of live plant cells, a venture which, if successful, could vastly reduce the need to chop down trees.

If successful, the project will get $255,000 in Government funding over three years. That seems like a proverbial drop in the bucket for an innovation that could change the future of our planet in one of the most dramatic ways possible. Leung certainly seems to think it has that potential. “Although challenging, there is potential to use live cells as an advanced manufacturing material in a yet-to-be invented, new industry,” he says, adding that bio-printing has already been demonstrated with live green algae cells. “It is possible that other types of plant cells, such as the wood-forming cells of eucalyptus trees, could be used as bio-printing materials. Hence, it is a potential, socially acceptable opportunity for sustainable economic development derived from native forests.”

Others certainly see the potential, too. Science and Innovation Minister Steven Joyce announced on Thursday that Leung’s project is among 10 seed projects to develop disruptive technology for industry that will – all together – receive $826,000 in funding this year from the Science for Technological Innovation (SfTI) National Science Challenge.

David Leung.

Leung says the end goal of his project is to be able to 3D print wood without the need for the destructive harvesting of live trees. “Live eucalyptus tree cells will be prepared specifically for bio-printing,” he explains. “They will be physiologically primed in a 3D structure in the biotech lab at the University of Canterbury, without any genetic modification, to be capable of responding to the appropriate triggers for transformation into a principal wood cell called a tracheid. The changes in the cells will be studied in relation to the characteristic morphological features and chemical properties of tracheids using various microscopic, histochemical staining and fluorescence techniques.”

So Leung’s project could be wondrous for the world’s wood supply. And considering we need trees to live, it’s also something that could help us all breathe a little easier. Literally.