Well, you can’t accuse Hutt Valley-based Fraser Engineering of lacking ambition.

Speaking at a recent Technology Valley get-together, general manager Martin Simpson says it wants to be a billion dollar company.

The 60-year-old private company with 100 designers, engineers and fabrication and production specialists has tweaked what it makes a number of times over the years – with its latest incarnation having manufacture of fully-specified fire engines as one of its major product lines.

Fraser’s is now the largest fire engine manufacturer in the Pacific area, and one of the largest in the world. All of this has been achieved by ploughing profits back into the business, and NOT outsourcing to the likes of China. It means that the company has more than $20 million of manufacturing ‘kit’, from 3D laser printers, to laser cutters, 9-axis machine tools to powder-coating facilities.

However, all this machinery starts and interacts with a Solidworks 3D CAD design software. (Martin noted that there’s a very large bill that the company has to pay for licence fees for this capability as one of the largest privately-owned users in New Zealand).

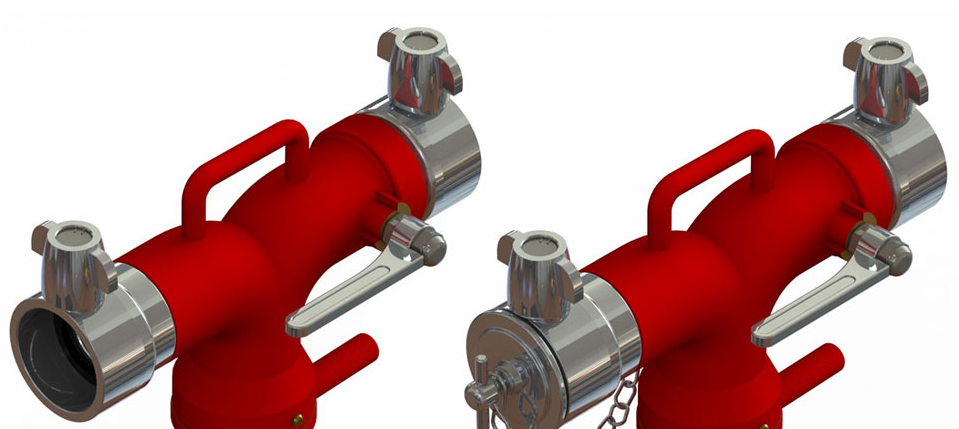

As a result Fraser’s is able to barcode-view the manufacture of every single part of the appliance, control valves, nozzles, hose reels and host of other components that make up a fire engine (or any other job it does for outside clients). From materials to drawings, purchasing and all aspects of turning raw metal into often very complex finished components, Fraser’s can track the process and progress of any individual part.

Should a replacement part be required, Fraser’s can find its specifications virtually instantly, and be able to produce it on the spot if required.

By maintaining a design-led in-house manufacturing and engineering capacity, “we’re now a powerhouse that can compete with anyone in Australasia,” Martin says.

“In fact, we’re advancing our manufacturing capability so quickly, our opposition can’t keep up.”

This in-house expertise also means that Fraser’s know to a few cents, how much an item costs to manufacture. Detailed information and internal reporting such as this is one reason that Fraser’s is now building 20-30 fire engines at any one time.

The company also has an intellectual property strategy that isn’t based on patents.

“The way we do it is to keep ahead of the competition,” says Martin. “If you copy you will never lead.”

Martin is also dubious (to say the least) about some of the ‘advice’ received over the years from government ministries.

Fraser’s deliberately didn’t outsource parts of its manufacturing to China. An observation he’s made of other engineering companies who have done so, is the waiting and co-ordination required to make sure hundreds of parts arrive on-time to create the component. This wait, and just as important the resultant delay in getting paid by your own customers is part of the reason the company has been so insistent on being a one-stop-shop, and/or outsourcing some manufacturing elements to local collaborative partners.

Control of the process is key.

“Don’t sell your assets,” was one of Martin’s take-home points. “It keeps you in control.”

He says an exemplar company for Fraser’s is Rosenbauer.

They are often asked (with incentives) whether they would also like to establish themselves over the ditch. In the meantime though growth will come through being smarter than their opposition.

That, and no doubt, a large degree of listening to themselves and not to others who don’t have skin in the game.