Cast an eye around your home or office and it won’t be able to travel far without coming across some sort of electronic device, be it phone, laptop, tablet or TV. Our production and consumption of technology is more rapid than ever, but it’s also costing the planet greatly.

A 2017 e-waste report by the United Nations University reports e-waste has reached record levels at 44.7 million tonnes – or the weight equivalent of nine Great Pyramids of Giza, or 4500 Eiffel Towers. Only 20 percent was recycled properly, with 80 percent thrown into a landfill or discarded.

Back home here in New Zealand, people discard 100,000 tonnes of e-waste per year, while a 2018 United Nations report also named and shamed New Zealand as one of the world’s largest generators of e-waste and as the only OECD country without any national regulations.

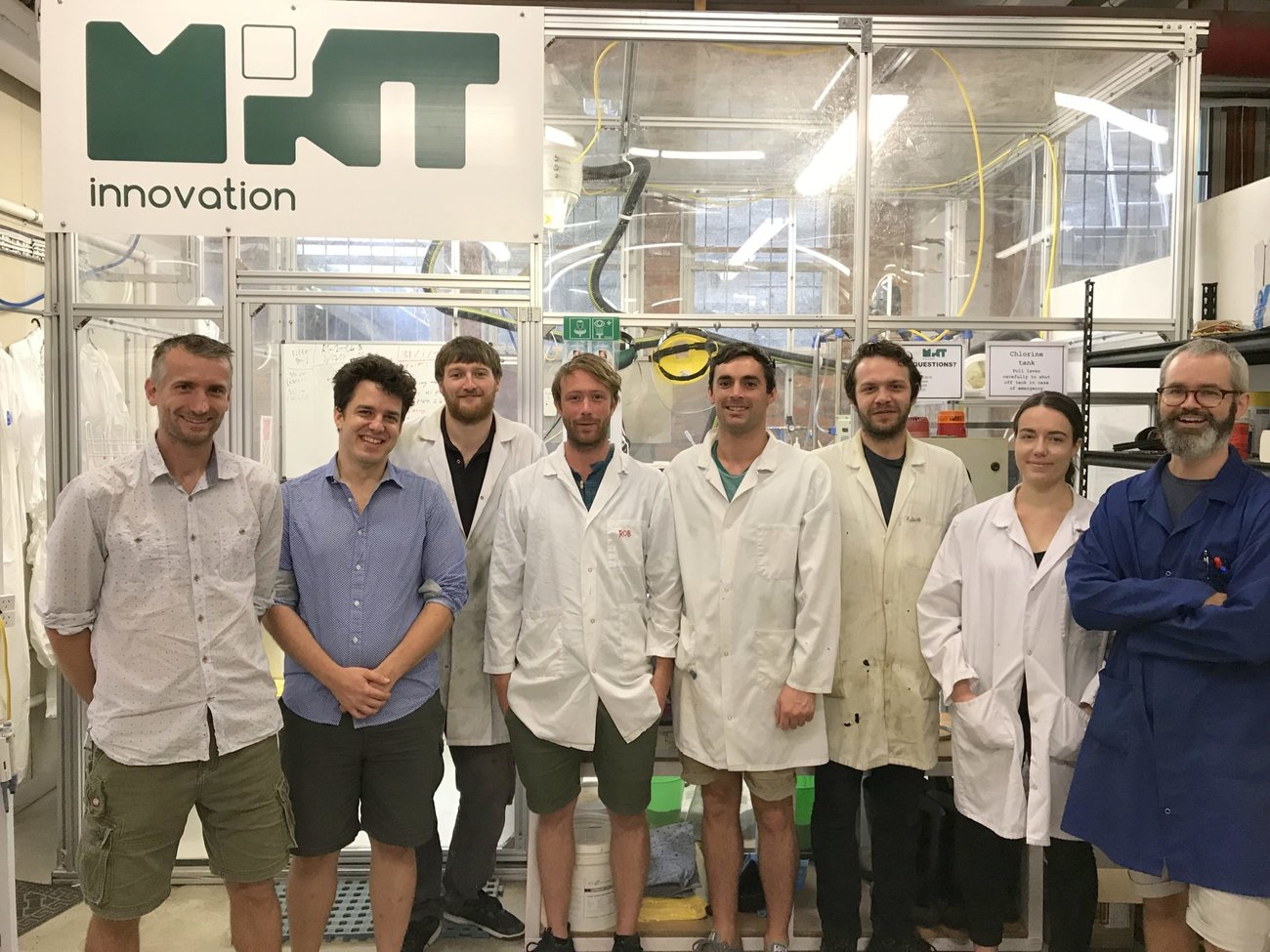

Enter Mint Innovation. The Auckland-based company has developed a biotechnology solution that used chemicals and microorganisms to turn waste into gold – or in other words, to recover valuable metals from electronic waste.

As well as this, the process it uses to do so is gentle on the environment and happens at the point of collection, instead of having to move the waste to landfill.

The company was co-founded by Dr Will Barker, formerly a senior executive at Lanzatech.

He left when the company relocated overseas and established a new venture, Mint Innovation, alongside co-founder Matthew Rowe in 2016. The company has been based out of Level Two deep tech hub (the former home of Lanzatech and Rocketlab) for the last two years perfecting the technology at a pilot scale.

Mint Innovation’s process works by leaching metals – including gold – from printed circuit boards, a thin electronic feature that is used in everything from computers, to TVs, to mobile phones.

Chief science officer Dr Ollie Crush says if these circuit boards aren’t recycled correctly, they can be extremely destructive for the environment.

“Waste printed circuit boards are a hazardous material comprising a mixture of heavy metals that may leach into waterways from landfill,” Crush says.

“Some printed circuit boards are collected for export to smelters for burning, with greenhouse gases produced as a by-product. Worse still, an unknown portion of waste circuit boards are exported illegally to developing nations, where the rudimentary extraction methods used result in catastrophic environmental and health outcomes.”

Crush says printed circuit boards make up approximately three to four percent of the 100,000 tonnes of e-waste that makes it into New Zealand landfill, which equals about $50 million of metallic value.

But even if someone was wanting to collect e-waste in New Zealand, he says there are no facilities locally to process them, so it has to be sent to smelters in Europe or Asia through a complicated logistics chain.

Mint Innovation wants to change this by having facilities that can leach the resources on site in individual cities. Most recently, it has partnered with Remarkit, an e-waste collector, to build a metal recovery plant in Auckland and carry out the process on a much larger scale than ever before.

“By recovering value in the city or region of collection, Mint Innovation can provide recyclers a faster and higher payback in a transparent and environmentally responsible manner. Furthermore, the metals recovered can be fed straight back into the local ecosystem, providing support for an evolving circular economy,” Crush says.

The park will be up-and-running in 2019. Currently, Mint Innovation is raising $4 to $5 million in private investment to build the plant, with Crush saying overseas funding options are also being explored.

Speaking of funding, Crush says this has been one of the biggest challenges. Even though there’s been significant amounts of capital raised from local investors and support from government agencies such as Callaghan innovation, the Ministry for the Environment and NZTE, the tech Mint Innovation is creating is breaking new ground, so is a resource and capital-intensive process.

Most recently, the company received a $80,000 grant from the Government’s Waste Minimisation Fund. Crush says this is going towards a study into how a New Zealand metal recovery plant should operate.

“Following completion of this project, we will be ready to invest the necessary capital to make this plant a reality,” he says.

And if all goes to plan, this technology could be rolled out across urban centres throughout the world. After all, Crush says the company has global ambitions.

“Each Mint plant deployed has the potential for returning tonnes of gold, copper and other valuable metals to any local economy,” he says.

The founding team have a strong commitment to New Zealand and cleantech. As such, we are excited to be developing and growing the technology in New Zealand, while working hard internationally to deploy Mint’s game-changing technology across the globe.”